References

Our references

Ekströms Värmetekniska AB have during many years supplied heat exchangers such as Economisers, Flue gas coolers and Air preheaters and several thousands meters of different kinds of finned tubes for all kind of applications.

More than 1000 shot cleaning systems has been delivered since this cleaning metod was introduced more than 50 years ago.

Our customers can be found all over the world.

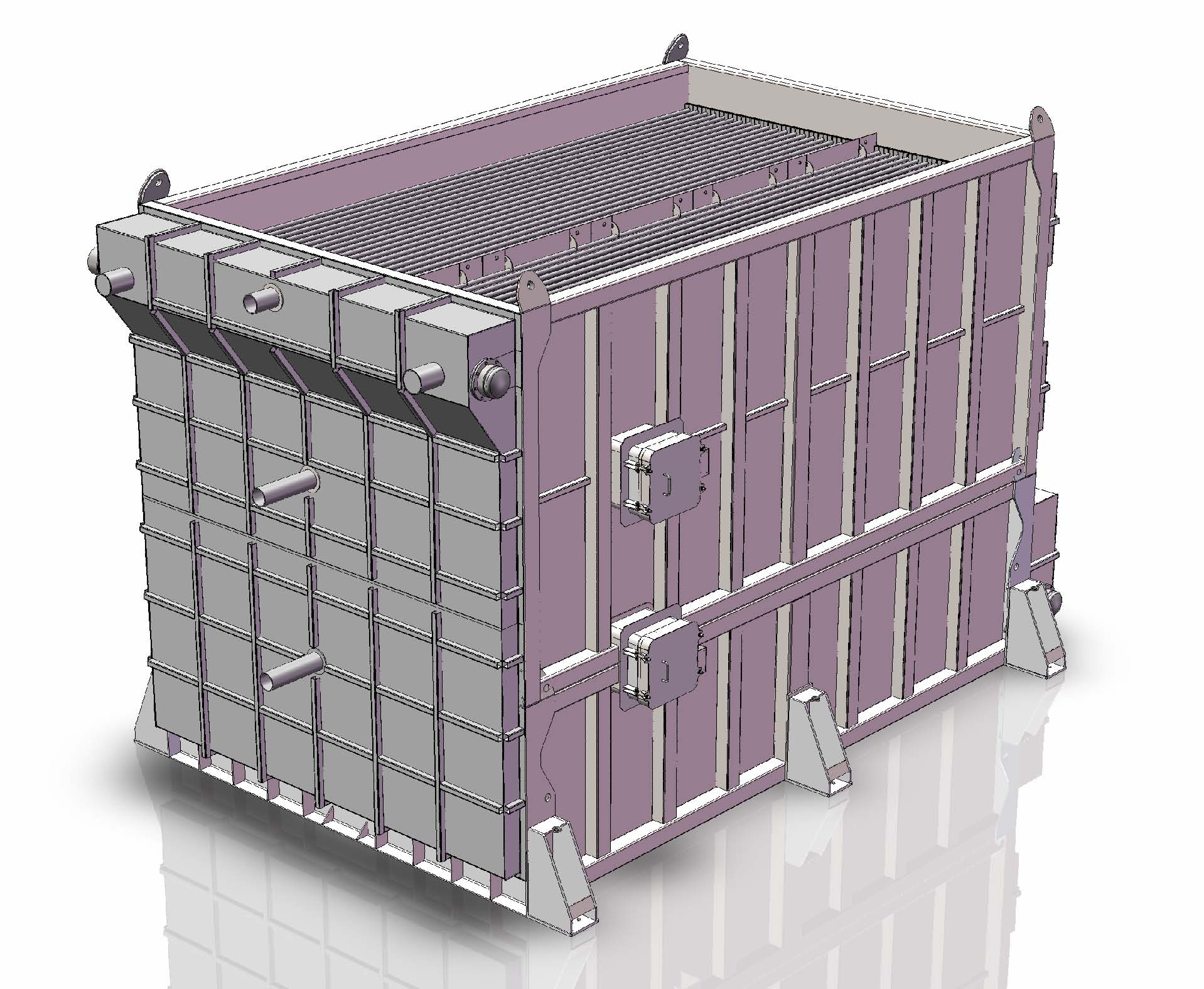

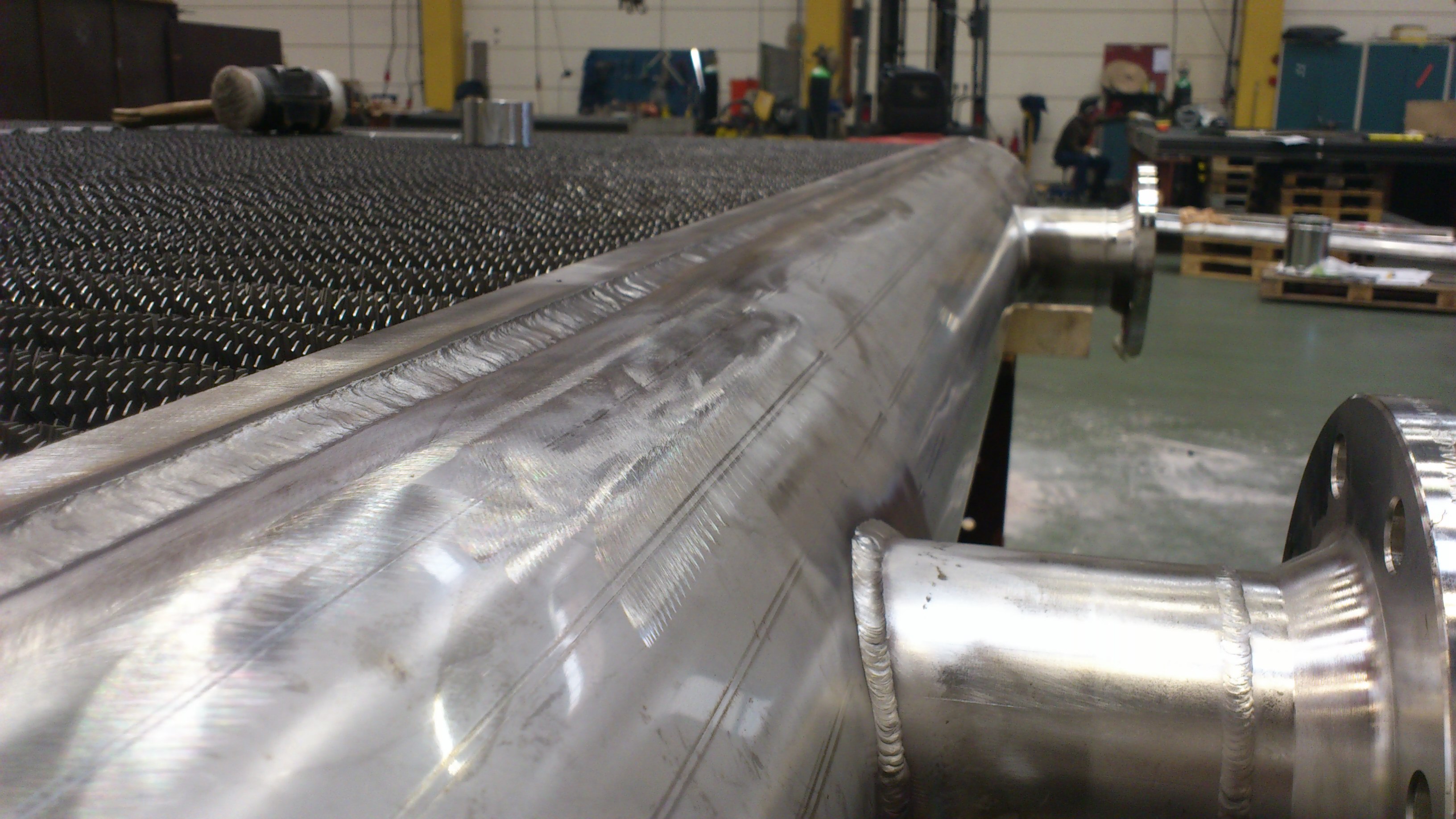

Flue gas coolers for Smurfit Kappa Nettingsdorf, Austria

Andritz choose Ekströms as the supplier for the two Flue gas coolers to Smurfit Kappas new recovery boiler at Nettingsdorf mill. The flue gas coolers consists of Double fin tubes.

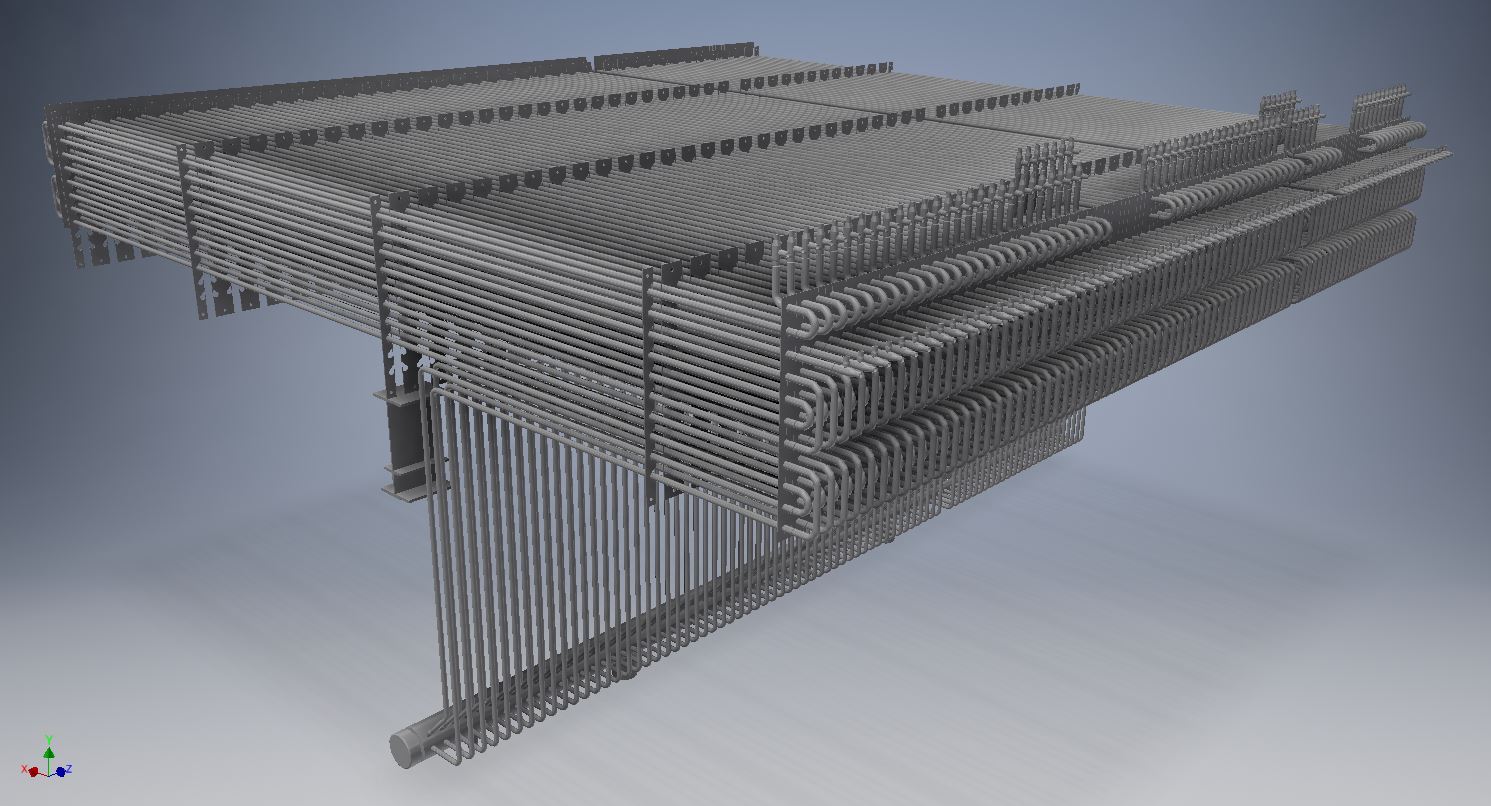

Economiser for Borås Energi och miljö, Sobacken, Sweden

Ekströms delivered the Finned tube Economiser for Valmets new Biomass fired boiler in Borås. The Economiser consists of Double fin tubes with a total heating surface of 8.465m². Delivery was made in two units with a weight of about 84 tons each.

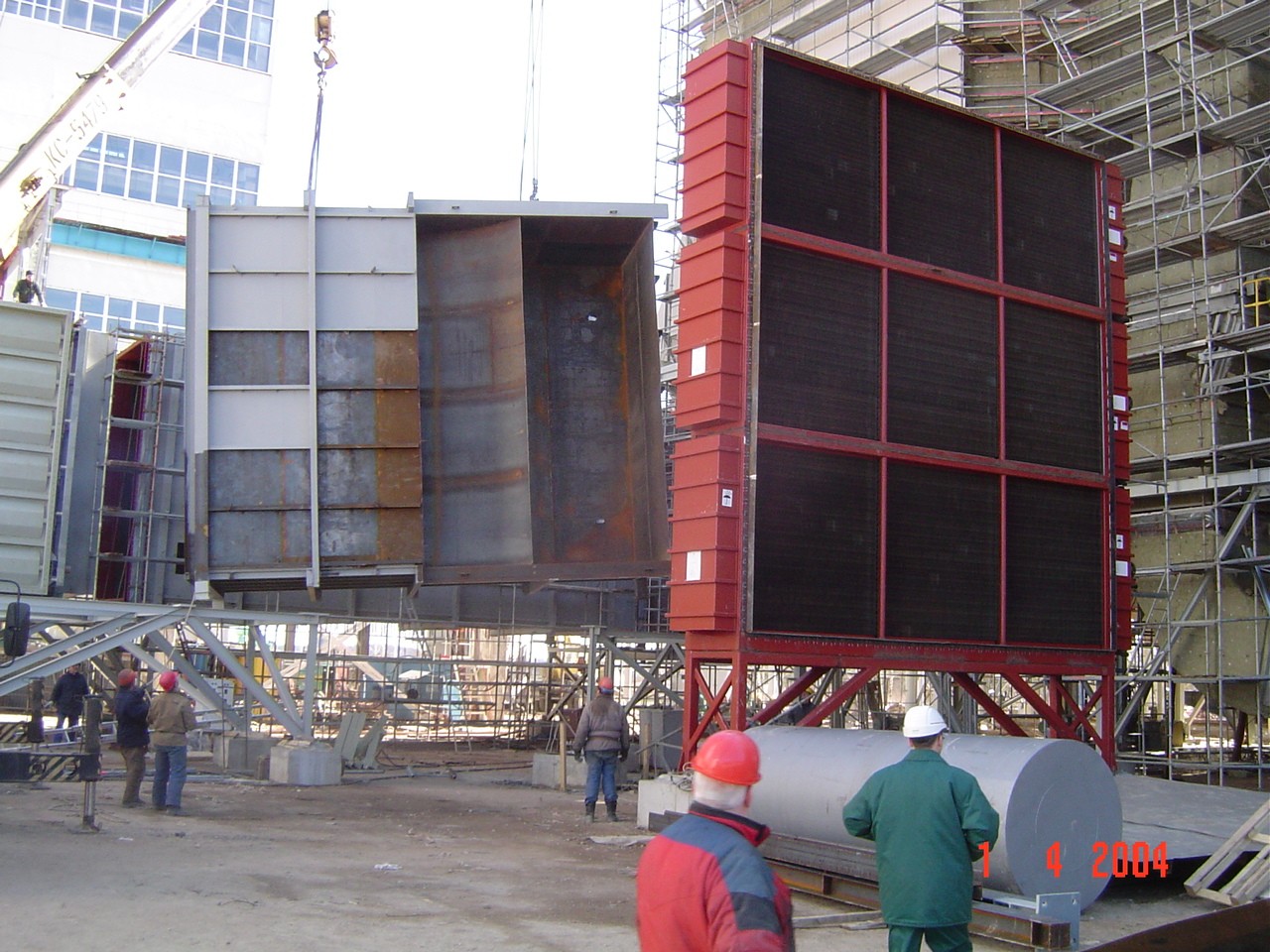

Flue gas cooler for SCA Östrand , Sweden

Andritz choose Ekströms as the supplier for the Flue gas cooler to SCA Östrand as part of the capacity increase in the Helios project. The flue gas cooler consists of Double fin tubes with a total heating surface of 11.126m² and a total heat output of just over 12 MW.